As with all common architectural and structural aluminum will corrode under certain conditions. The oxidation can dissolve when it contacts strong acid or alkaline solutions.

Iron oxide rust is a soft red colored metal that begins to expand and flake off as it is chemically transformed which exposes more of the underlying steel or iron to the air and the process continues until the metal is completely transformed.

Is aluminum oxide good for the environment. Anodic aluminum oxide AAO is a nanoporous structure likened to a honeycomb with high-density arrays of uniform and parallel pores. This shelf life test is a good indicator for an inert chemically behavior of the electrolytic system against the dielectric aluminum oxide layer because all chemical reactions are accelerated by high temperatures. Nearly all todays series of capacitors fulfill the 1000 hours shelf life test which is equivalent to a minimum five years of storage at room temperature.

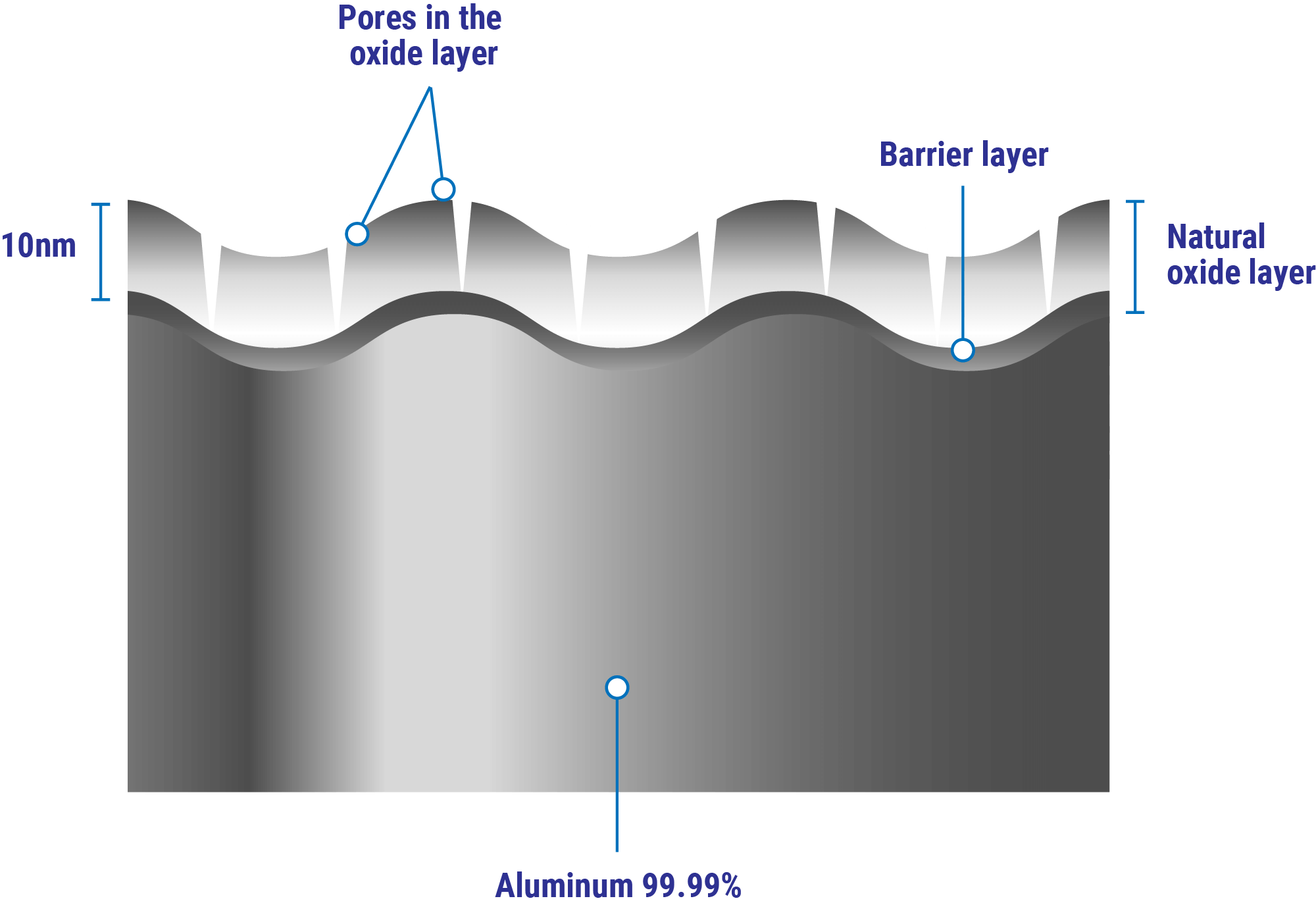

Aluminium aluminum in American and Canadian English is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals at approximately one third that of steel. It has a great affinity towards oxygen and forms a protective layer of oxide on the surface when exposed to air.

Aluminium visually resembles silver both in its color and. Aluminum foil is typically less than 015 mm 00060 in thick. It can be about 15 times thinneras thin as 001mm 00004in.

Pure aluminum reacts rapidly with air to form a rustproof protective layer of aluminum oxide. Many cooking pots pans and tools are made of aluminum. When exposed to oxygen it forms aluminum oxide just like steel forms iron oxide but the difference lies in the chemical makeup of these two oxides.

Iron oxide rust is a soft red colored metal that begins to expand and flake off as it is chemically transformed which exposes more of the underlying steel or iron to the air and the process continues until the metal is completely transformed. The final product from the Bayer process is alumina or aluminum oxide which has the appearance of a white powder. The reduction unit of an aluminum plant consists of reduction pots or cells which are connected in series.

Each pot is made of a steel shell lined with carbon. Molten cryolite a fluoride mineral containing aluminum oxide is poured into each pot and carbon. Aluminum naturally generates a protective thin oxide coating which keeps the metal from making further contact with the environment.

It is particularly useful for applications where it is exposed to corroding agents as in kitchen cabinets and in vehicles. In general aluminum alloys are less corrosion-resistant than pure aluminum except for marine magnesium-aluminum alloys. Occupational limits exist in several countries for exposures to aluminium dust and aluminium oxide.

For non-occupational environments limits have been set for intake in foods and drinking water. The latter are based on aesthetic or practical rather than health considerations. Environmental Levels and Human Exposure.

Aluminium may be designated as crustal in origin and thus surface soils at. The resulting aluminum oxide is a thin hard layer that actually protects the metal from further corrosion. Aluminum oxide appears as a powdery white or dull gray coating.

As oxidation occurs it hardens and creates a protective layer over the newly exposed areas of corroded aluminum. The aluminum corrosion process is actually halted by oxidation the metal wont continue to deteriorate. Chemical Film on Aluminum also called by proprietary names of Alodine or Irridite is a thin clear or yellow conversion coating used as a primer for paint general protection to prevent aluminum from oxidizing or used in conjunction with masking of an anodized finish for conductivity properties.

While it may be somewhat confusing in that it is sometimes used with another finish when masked. The film can stay stable in other cases depending on the environment for example nitric acid at pH 0 glacial acetic acid at pH3 or ammonium hydroxide at pH 13. The oxide film can be dissolved in most strong acids and bases in which case the corrosion of the aluminum will be rapid.

As with all common architectural and structural aluminum will corrode under certain conditions. This is more. Aluminum alloys of Series 5xxx Al-Mg and 6xxx Al-Mg-Si show a good resistance to atmospheric corrosion.

The composition of selected Al alloys is shown in Table 1011. Alloys of Al 6061 6013 5052 and 5054 can be used in the atmosphere without any serious risk of corrosion. Anodizing is an electrochemical conversion process that forms an oxide film usually on aluminum in an electrolyte chemical solution.

The aluminum parts are the anode thus the term anodizing and current is passed between them and a cathode usually flat aluminum bars through the above-mentioned electrolyte sulfuric acid is most commonly used. Argon due to its good cleaning action and penetration profile is the most common shielding gas used when welding aluminum. Welding 5XXX-series aluminum alloys a shielding-gas mixture combining argon with helium - 75 percent helium maximum - will minimize the formation of magnesium oxide.

Select an aluminum filler wire that has a melting temperature similar. When joined together in a similar environment corrosion can occur between anodized aluminum and stainless steel. Localized corrosion occurs because the oxidation of aluminum during the anodizing process makes it passive.

The oxidation can dissolve when it contacts strong acid or alkaline solutions. The removal of this oxide film starts the corrosion of the aluminum. We produce Aluminum Round tube aluminum square tubing Aluminum rectangular Tubing aluminum oval tube.

The most common alloy no. To produce an extruded aluminum tube is 6061 and 6063. Both of them have good corrosion resistance wearability and a good outlook for anodized aluminum tubes.

If sodium metal is relatively good at giving up electrons Na ions must be unusually bad at picking up electrons. A vigorous reaction takes place to give aluminum oxide and molten iron metal. 2 Als Fe 2 O 3 s Al 2 O 3 s 2 Fel By assigning oxidation numbers we can pick out the oxidation and reduction halves of the reaction.

Aluminum is oxidized to Al 2 O 3 in this reaction. Pure aluminum has a thermal conductivity of about 235 watts per kelvin per meter and an electrical conductivity at room temperature of about 38 million siemens per meter. Aluminum alloys can have much lower conductivities but rarely as low as iron or steel.

Heat sinks for electronic parts are made of aluminum due to the metals good thermal. US-based Wright Electric has announced a 100-seat electric short-hop aircraft slated to go into service by 2026. Itll either be powered by hydrogen or itll use recyclable metal in what the.

This process artificially changes the structure of aluminum oxide on the surface of the metal providing a surface finish that is more durable stain-resistant and corrosion-resistant. Bare aluminum is put through this process for many reasons. Some are purely aesthetic such as giving a shiny finish but others have an applied purpose.

Anodized aluminum doesnt chip or stain and if its. The thicker the aluminum oxide layer the more difficult for LED channels to deform the better quality the aluminum channel. For typical aluminum oxide the depth is up to 5 microns.

Our aluminum extrusions are treated to 10 microns which results in a hard aluminum oxide coating that is able to withstand chemical attack and other damage elements. All aluminum alloys form an oxide layer in the presence of airwater which protects the chemically-active aluminum from further reacting with the outside environment. The amount of corrosion resistance is dependent upon temperature airborne chemicals and the proximal working environment.

However under ambient circumstances 5052 aluminum holds up exceptionally well. Graphene Oxide is a derivative of graphitegraphene invented in 1849 and is well-known to be dangerously toxic to living bodies. Graphene oxide has a direct effect on human neurons and can be controlled from the outside with a magnetic field apparatus.

Graphene Oxide contains semi-conducting properties proportional to the level of oxidation. Its hydrophilic attracted to water and has. Aluminum is lightweight conducts heat well and is fairly inexpensive making it a popular choice for cooking.

Canadians normally take in about 10 milligrams of aluminum daily mostly from food. Aluminum pots and pans provide only one or two milligrams of the total. While aluminum has been associated with Alzheimers disease there is no definite link proven.

The World Health Organization. Wellste aluminium profiles for windows and doors are made of Aluminum 6063 Alloy Number it is the most common alloy number for producing aluminum window and door profile. 6063 aluminum alloy is widely used in building aluminium window extrusions and aluminum profiles doors It has good surface decoration after Powder coated surface treatment.

And it has good corrosion resistance.